FinishingFabrication Service

FinishingFabrication Service Product Details

Product Details | Product Name | Extruded Aluminum Enclosure | |

| Alloy Grade | 6063/6061 | |

| Temper | T4/T5/T6 | |

| Shape | As per provided drawing or sample | |

| MOQ | 1 Ton | |

| Surface | Mill finish, Polishing, Brushing, Anodizing, Electrophoresis, Wood grain, Powder coating | |

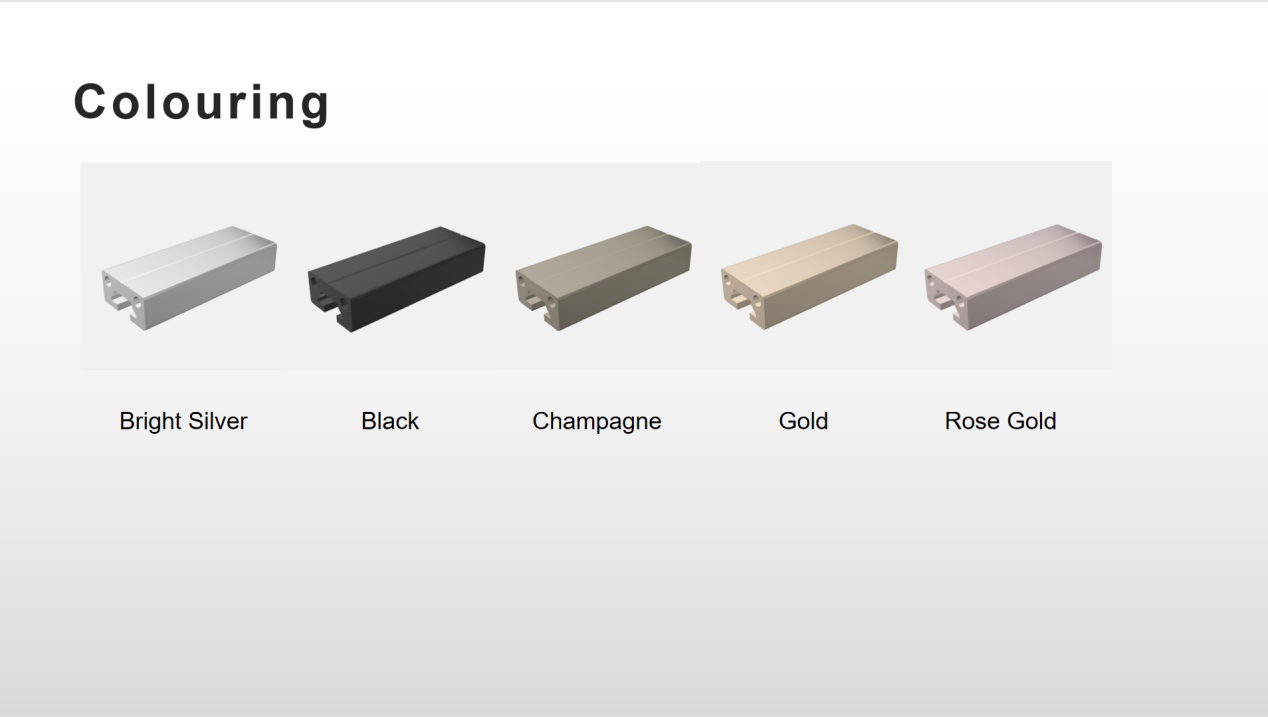

| Color | Silver, black, white, bronze, champagne, green, gray, golden yellow, nickel, or customized | |

| Film Thickness | Anodized | Customized. Usual thickness: ≥8 μm |

| Powder Coating | Customized. Usual thickness: 80-120 μm | |

| Electrophoresis Complex Film | Usual thickness: 16 um | |

| Wood Grain | Customized. Usual thickness: 60-120 μm | |

| Standard | High quality | |